#Allen datagraph systems derry nh software#

Software included: CMC4 Controller, Corel® Suite X3, PhotoGraV, TPCWin (vector cutting). Range of resolution (dpi): Vector to 1,200. Maximum materials weight accepted: 400 lbs. Maximum material size/production area: 78” X 150” (Larger production areas available.) Other notable features: U.S.-made, full-function control joystick, multiple-job queue. Maximum materials weight accepted: Unlimited Maximum material size/production area: 4’ X 4’ to 5’ X 12’ The information provided is from surveys distributed to manufacturers in late 2007, along with additional research. For the latest information – and before making any purchase commitment – always contact manufacturers at the telephone numbers or Websites provided with each listing. Models can change, and prices can vary at any time. LaserProUSA machines are manufactured by GCC, for example similar models are available with the Pinnacle™ nameplate from Engravers Warehouse. Some companies also get their laser engravers from original equipment manufacturers (OEMs), such as GCC in Taipei, Taiwan. Other software from the engraving industry, like PhotoGraV from ImageLaz LLC can address other needs, such as creating a halftone-dot effect for reproducing photographs. All the machines use lines (or vectors) as a pattern for output instead of using specialized software, the lasers can take data (and laser setting) directly from vector-based graphics software, most notably Corel Corp.’s CorelDRAW®.

#Allen datagraph systems derry nh driver#

It’s worth noting that many manufacturers offer a print driver for software. This also involves doing a job in stages, depending on the working (production) area of the laser, in a tiling routine of etching consecutive smaller sections form a larger image. Some of these enclosed units have ways to slide larger, longer pieces through the machines.

A flatbed has an open-gantry configuration much like a CNC an enclosed cabinet puts everything inside a contained space, mainly for safety at close quarters. There’s also an indication of machine design. There’s also a listing for the amount of weight a machine can handle, since there’s more bulk to a monument or 2 ft² marble tile than a commemorative acrylic award.

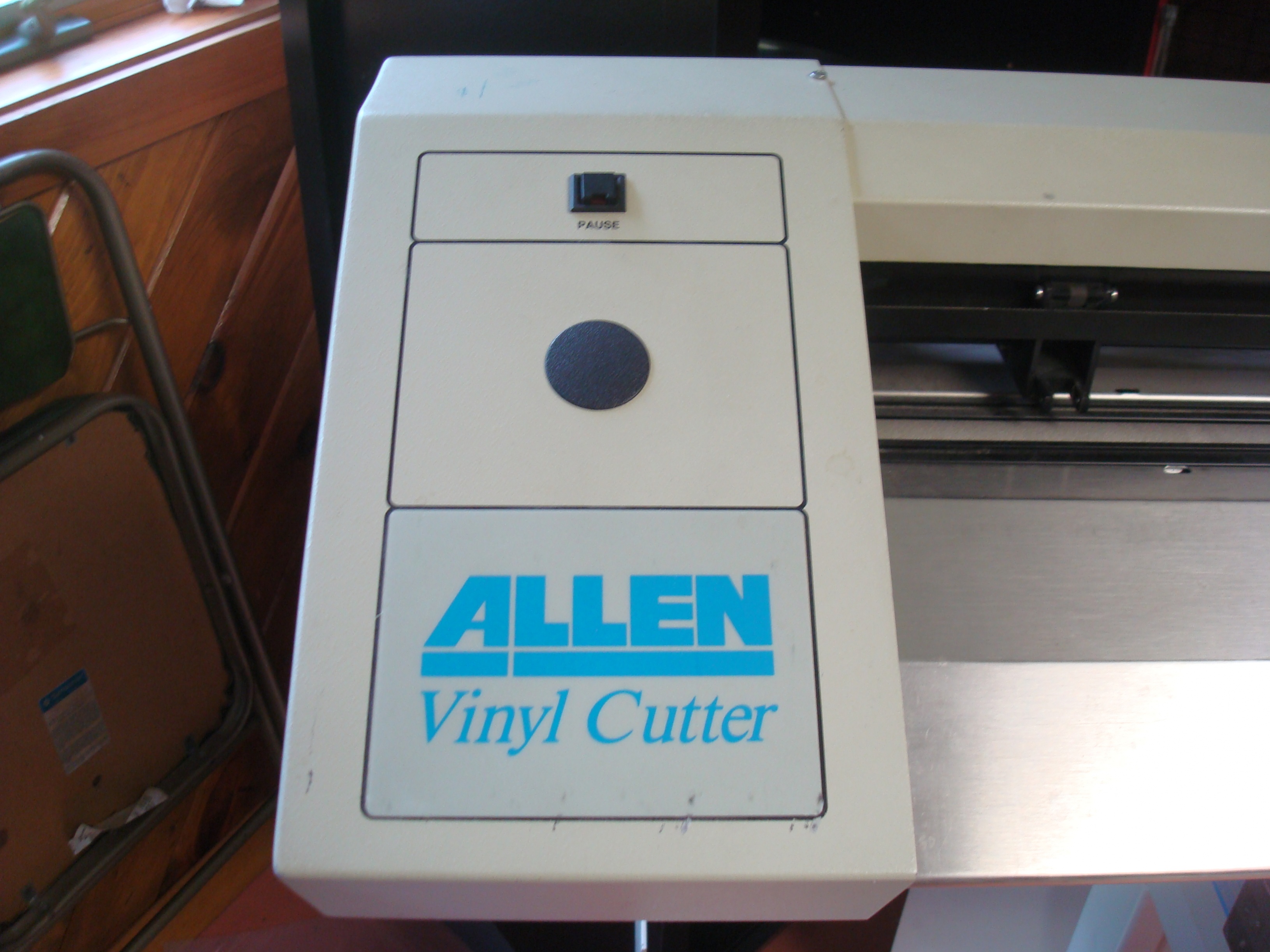

The listings here are from early 2008.įor this survey, a machine had to have a production area – the space where the laser can do its work – of at least 12” X 12”. Currently, ADSI has customers in over 40 countries across the world, and with their help continues to innovate and meet the changing needs of their customers.Note: This information is being updated. ADSI is determined to continuously better their systems and launch new products that make the best use of design, applications, and technology. With optimism, inventiveness, and a strong dedicated team, ADSI is thriving in the rapidly changing world of technology.Based in Derry, New Hampshire, ADSI has a variety of products and systems that are suitable across several industries. In 2000, Michael Elliott became President of ADSI, and has since led the company to success through the ups and downs of the American economy. All of the products ADSI sells are made in America. Established in 1980, ADSI has grown tremendously, becoming a leader in its industry. (ADSI) is a technology leader in the manufacturing and selling of digital micropress label systems, cutters, plotters, and recording devices.

0 kommentar(er)

0 kommentar(er)